免费体验

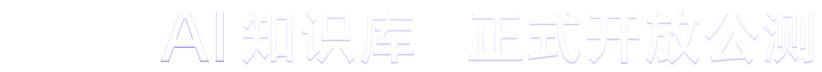

生产基地和分支机构遍布全国各地甚至海外,产生的大量文档资料分散在各地员工的电脑上,缺乏统一的存储管理平台,查找、应用难。

设计研发、生产计划、质量管理、仓储等部门间进行业务合作时,经常通过邮件/QQ/微信等方式来回发送和修改同一份文件,信息干扰大、效率低,操作不便。

总部给分公司、代理商、供应商等内外部机构下发文件、收集资料时,需要一个个发送和接收文件,手动下载、整理归档,耗时费力,效率低、人工成本高。

设计图纸、产品资料等机密文件难以全程监控流转过程,无法杜绝文件被下载后外发给其他人,而机密文件一旦外泄很可能会给企业造成很大损失。

现状痛点:

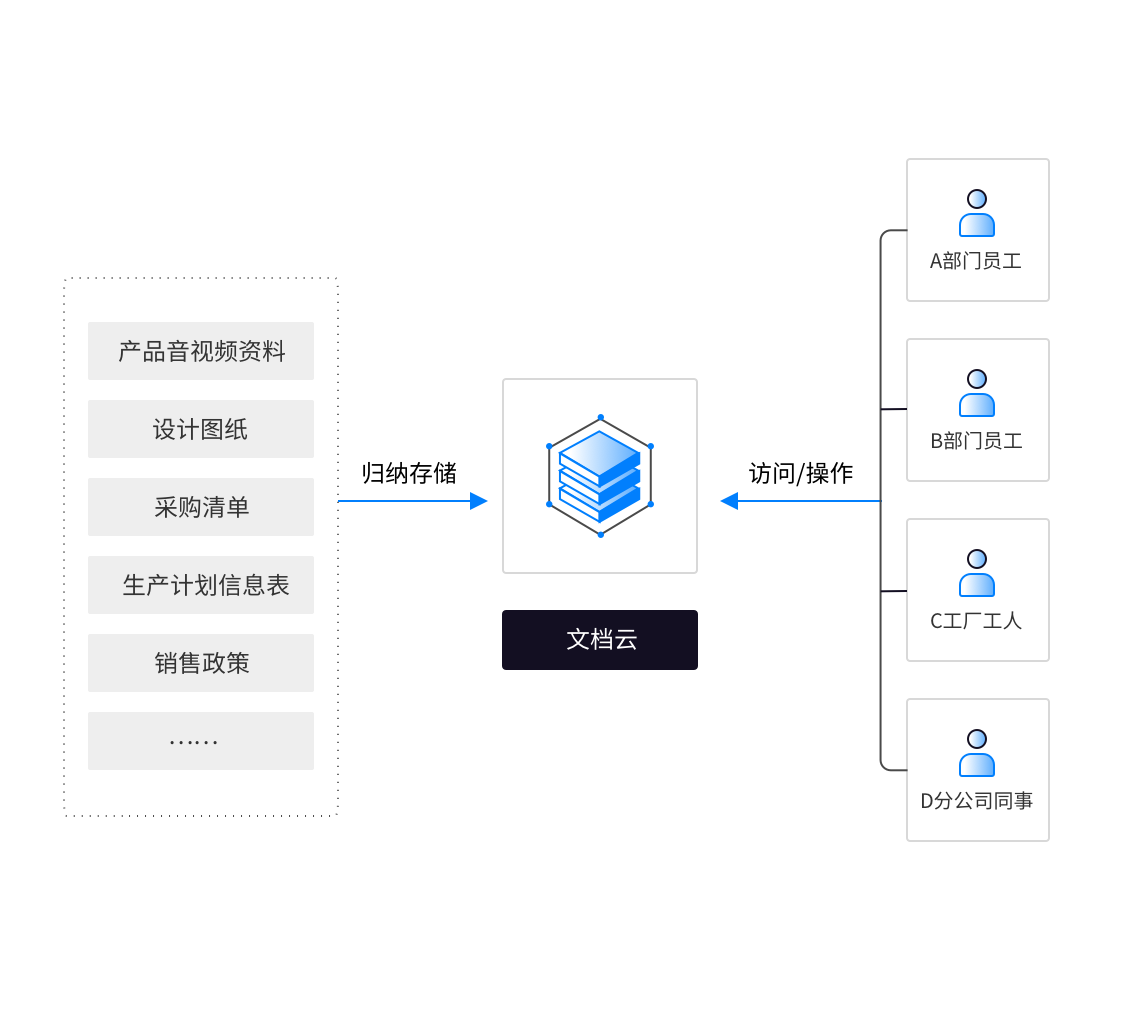

资料分散运用难:大量文档资料分散存储在各地员工的电脑上,很难有效、统一地管理和利用,一旦电脑硬盘损坏、病毒入侵、服务器瘫痪,会造成资料丢失。

人工管理成本高:海量文件的管理也是个难题,经常需要专门安排员工定期收集整理再上传至企业知识库,管理成本高。

生产工人培训难:为了保障各个工厂标准化安全生产,需要不定期对工人进行各种培训。然而每个车间培训内容不同,缺乏线上知识库供员工随时在线学习。

应用方案:

通过360亿方云,根据组织架构、不同项目创建共享文件夹,文件夹中的所有成员可以随时随地新建/上传重要的办公资料,实现集中存储与备份、成员间实时共享、精准检索与便捷访问。公共知识库可沉淀海量培训资料,满足以工厂或车间为单位组织员工在线学习不同内容的需求。

现状痛点:

存储安全难保障:制造行业在产品研发、设计阶段会产生大量的机密性设计图纸,它们散乱存放在员工电脑中,难以保障安全性,流转不可控,存在泄露的风险。

图纸预览不便:设计图纸需要及时提供给生产制造部门作参考,也经常需要导出给外部客户预览,然而需要安装专业软件才能查看源文件,十分不便。

离职时交接难:员工离职时,如果图纸交接出现遗漏、交接不齐等情况,则存在图纸丢失和机密外泄的风险。

应用方案:

360亿方云支持CAD等120+种专业格式文件随时预览,可以直接在线预览设计图纸。360°文件防泄露(DLP)方案,通过“生产-流转-归档”的文件全生命周期管理和“云端-本地-外发”的全方位终端安全防护体系,保障设计图纸安全不外泄。员工离职时,可以将360亿方云上的文件一键交接给新的接管者。

现状痛点:

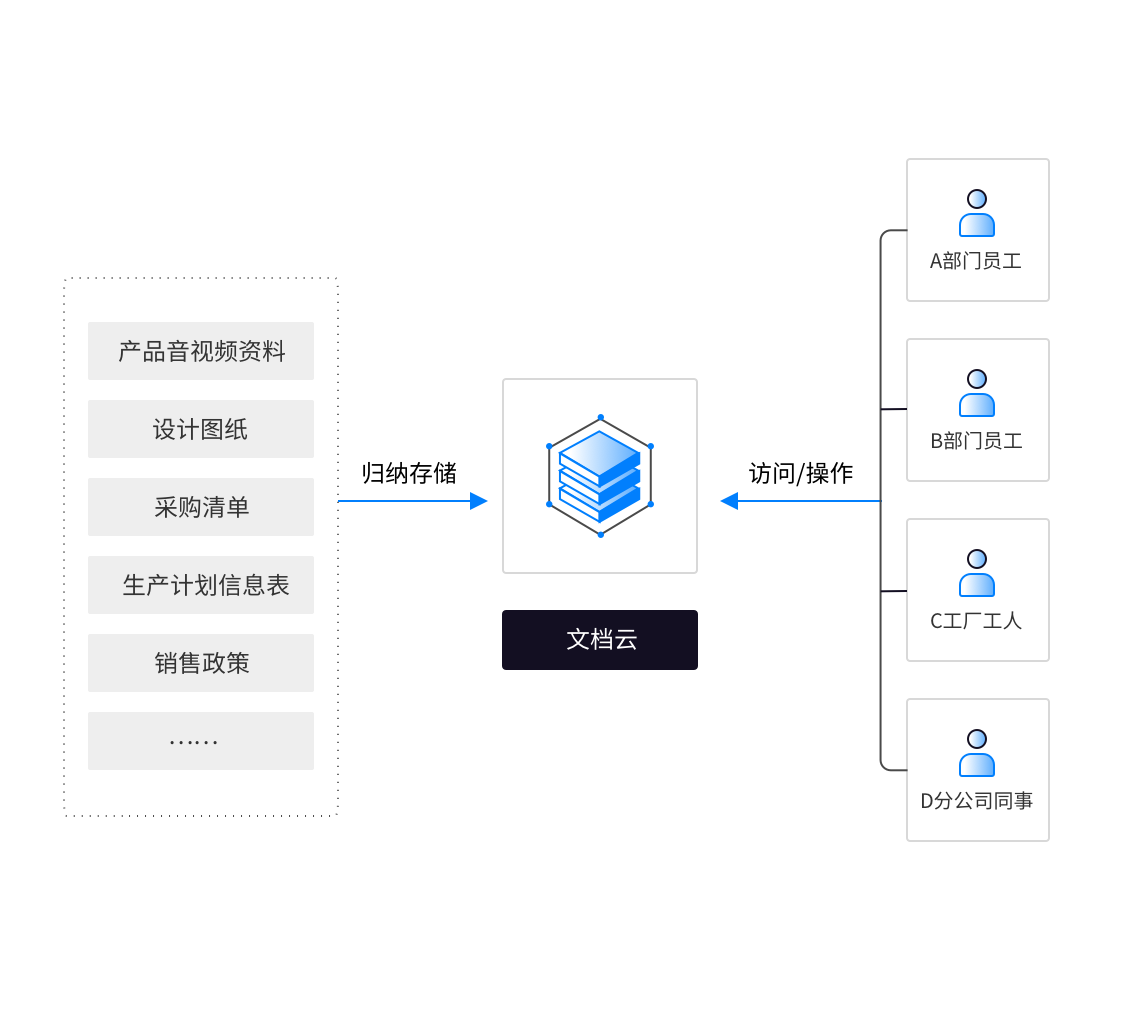

跨部门协作效率低:生产管理部需要和制造部员工反复沟通、修改,才能产生最终的生产计划文件,这一过程中大多通过QQ/邮箱等方式来回发送文件,沟通成本高、效率低,无法灵活指导仓储部门调整储备,容易造成库存过量或短缺。遇到客户需要提前交货、产生临时插单需求时,缺乏高效的信息同步工具,会造成各部门间节奏混乱。

应用方案:

生产管理部成员可以邀请制造部、仓储部员工加入共享文件夹,并@制造部成员,对生产计划表进行通知和评论;制作部成员可以回复消息或直接修改,大大降低沟通成本。确认下来的生产计划表可以一键分享给仓库,通知备货;仓库主管可以订阅生产计划文件,第一时间掌握文件更新消息。

现状痛点:

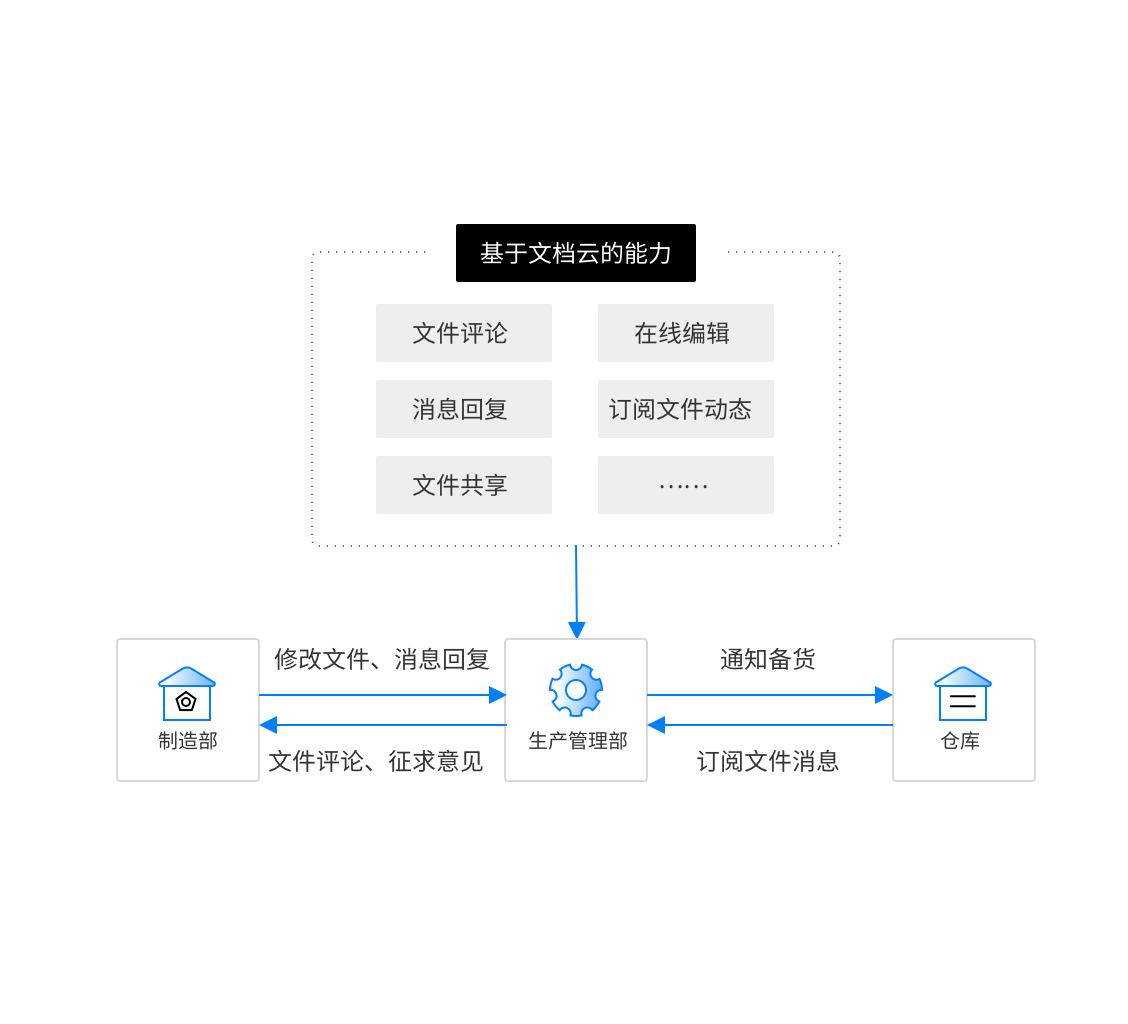

文件制定效率低:输出质量管理文件所需的资料一般通过邮件/微信/QQ等方式被收集整合,收集效率低;期间还需要多次确认和反复修改,导致员工电脑上多个文件版本并存,容易用错版本;低效的文件协作过程也常常导致质量评估周期被拉长。

应用方案:

通过360亿方云,质量管理部可以对指定成员发起文件收集,各成员将文件上传至指定文件夹即可;支持多人同时对文件进行在线编辑,修改后的最新内容实时同步,无需反复上传;保存每次修改的记录,最多支持100个历史文件版本随时追溯。

现状痛点:

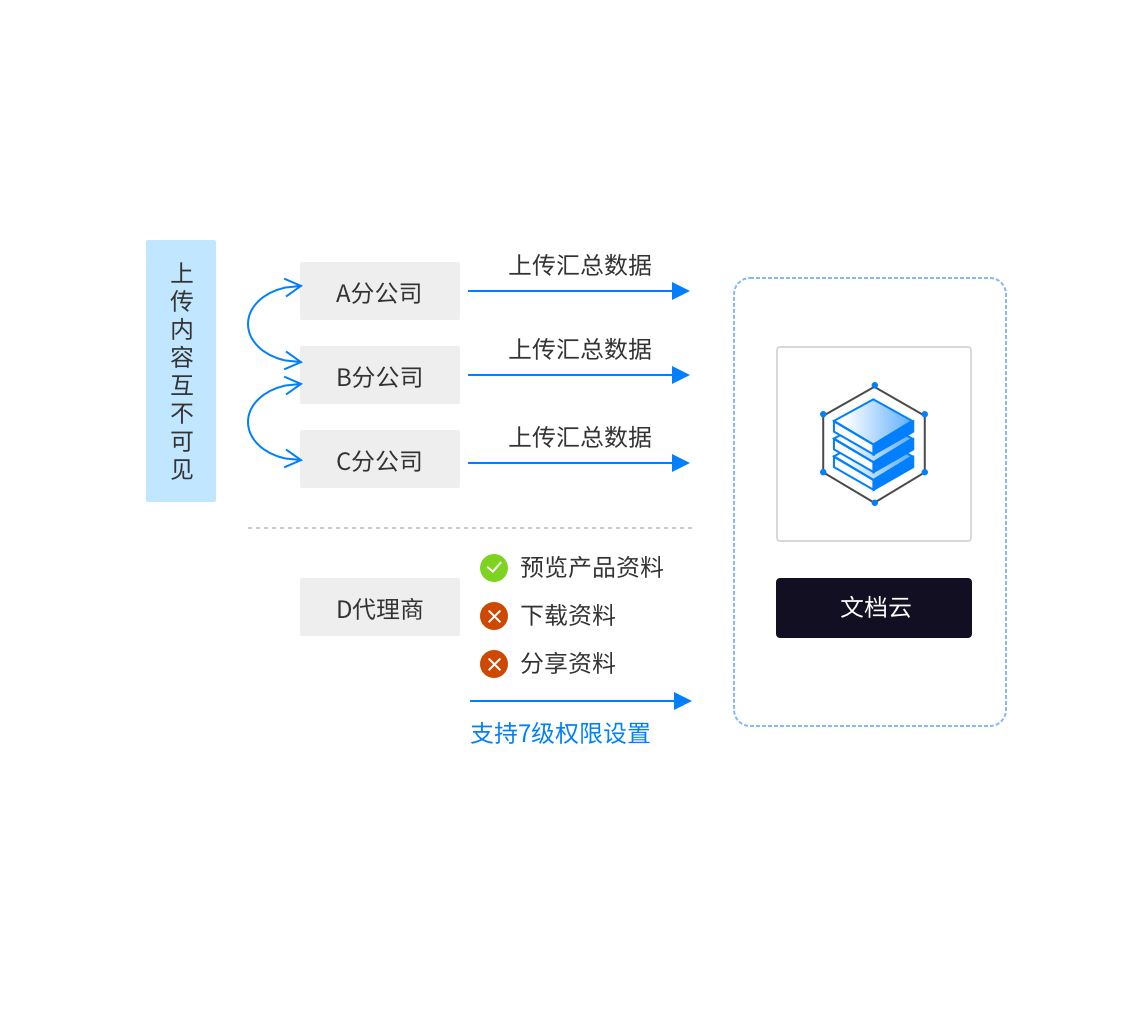

总部资料下发难:总部经常需要向分公司/代理商下发销售政策、产品手册、产品安装视频等。文件超出大小限制则无法通过微信、QQ、邮箱等发送,微信、QQ中接收的文件几天后就会过期无法下载;文件流转不可控,存隐患。

分公司数据汇总难:总部需要定期收集各地分公司的销售数据,各区域负责人通过邮件以附件形式发送给大区,各大区负责人整理后发送给总部,再由总部工作人员一个个单独下载、整理归档,层层周转,重复工作量大,周期漫长。

应用方案:

通过360亿方云,总部可与分公司、代理商实现文件共享,无需邮件发送给对方;并能给分公司员工/代理商设置权限,例如只能预览不能下载和分享,规避文件外泄。总部工作人员可以指定分公司员工将数据上传至指定文件夹,快速完成数据收集,且做到各区域汇总数据互不可见。

现状痛点:

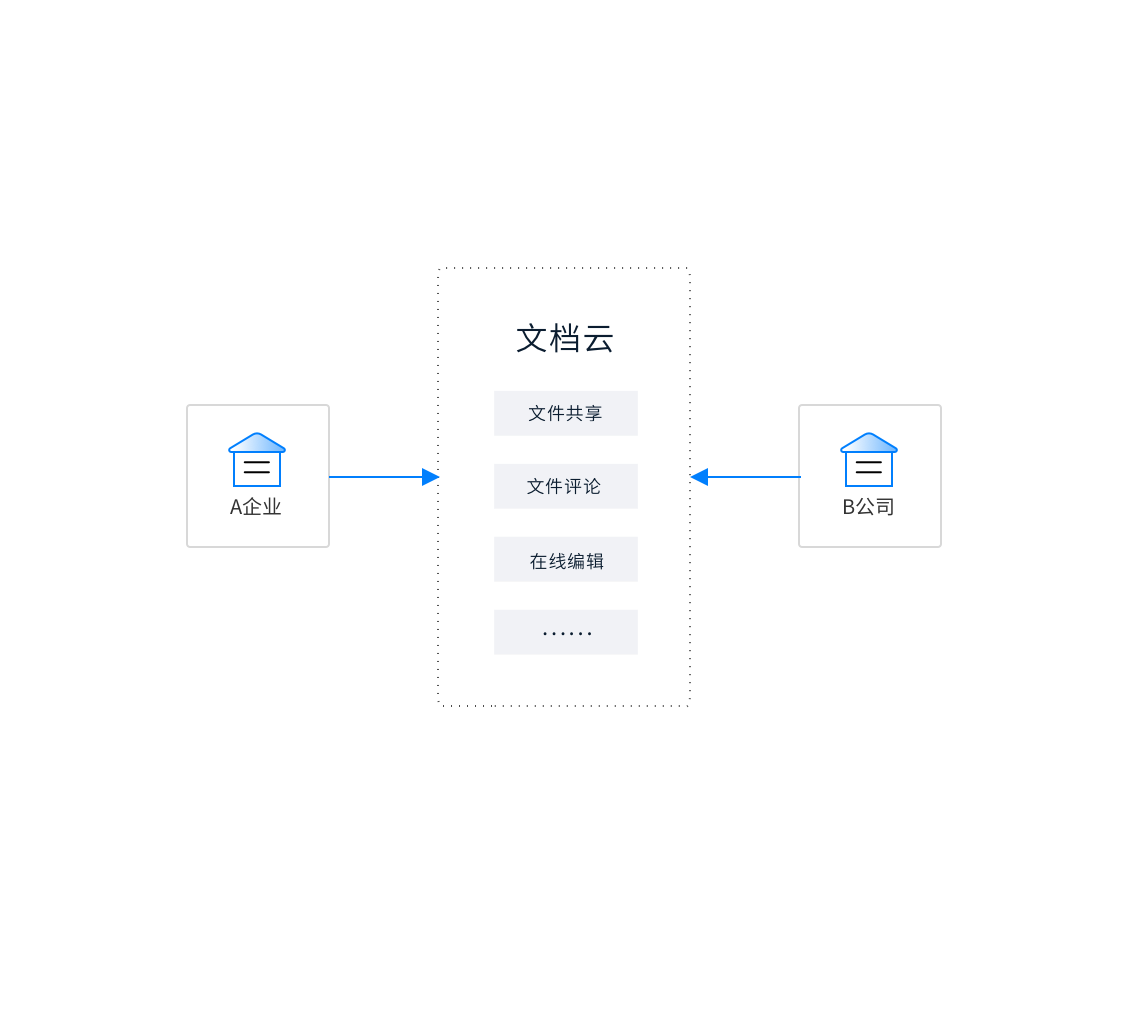

跨企业协作效率低:某些制造企业和下游供应商(外部企业)之间的沟通协作往往仍要通过邮件、QQ或传真等方式完成,过程中容易造成消息同步滞后、信息丢失,导致供货不够及时,出现库存不足或过量。

应用方案:

通过360亿方云,制造企业可以和外部供应商之间搭建信息交互的桥梁。例如,采购部人员可以邀请外部物料供应商人员加入共享文件夹,及时上传采购计划等文件,并随时随地进行沟通、评论、回复,保证采购工作及时、精确地推进下去。

现状痛点:

资料分散运用难:大量文档资料分散存储在各地员工的电脑上,很难有效、统一地管理和利用,一旦电脑硬盘损坏、病毒入侵、服务器瘫痪,会造成资料丢失。

人工管理成本高:海量文件的管理也是个难题,经常需要专门安排员工定期收集整理再上传至企业知识库,管理成本高。

生产工人培训难:为了保障各个工厂标准化安全生产,需要不定期对工人进行各种培训。然而每个车间培训内容不同,缺乏线上知识库供员工随时在线学习。

应用方案:

通过360亿方云,根据组织架构、不同项目创建共享文件夹,文件夹中的所有成员可以随时随地新建/上传重要的办公资料,实现集中存储与备份、成员间实时共享、精准检索与便捷访问。公共知识库可沉淀海量培训资料,满足以工厂或车间为单位组织员工在线学习不同内容的需求。

360亿方云线上SaaS平台为用户存储和管理了20亿+份文件,涵盖120+文件格式,拥有业内领先的亿级文件存储能力,满足用户海量数据存储的需求。

360亿方云稳定运行近十年,架构稳健,可灵活扩展,架构服务于50万+企业用户,具备千万级高并发实战能力,无使用瓶颈。

提供覆盖“生产-流转-归档”的文件全生命周期管理和“云端-本地-外发”的全方位安全防护体系,兼顾数据安全和互联网级产品的优越体验。

360亿方云至今已为晶科能源、吉利科技集团、西奥电梯、起帆电缆、长安汽车、通威太阳能、巨久轮毂等众多知名制造企业提供服务,拥有海量制造业用户服务经验。

晶科能源是全球极具创新力的光伏企业,以及全球为数不多的拥有垂直一体化产业链的光伏制造商。360亿方云为晶科能源搭建「晶科云盘」,并为其建设上海、海宁、上饶等4个独立的数据中心,提供文件的全生命周期安全管理。通过文件共享空间,国内团队与海外团队之间轻松实现了高效协同办公,移动端也可以随时随地打开晶科云盘APP,实现便捷移动办公。